PPS Dust Filter High Temperature Filter Bags

PPS dust filter high temperature filter bagsThe dust collector bag is made of a textile filter cloth and a non-woven fel

Description

Basic Info

| Filtration Grade | HEPA Filter |

| Filter Bag Sectional Shape | Round Bag |

| Filter Bag Environment | Room Temperature |

| Cartridge Installation | Top Mounted |

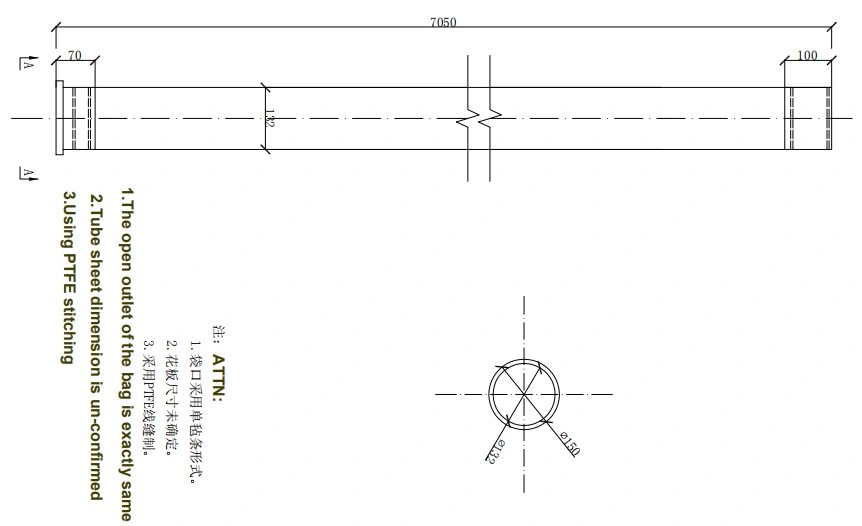

| Diameter | Customized |

| Length | Customized |

| Service Life | 1 Years |

| Thickness | 1.8-3mm |

| Top | Snap Band |

| Materials | Polyester, P84, Nomex, PPS Ects Customized |

| Function | Filter Element for Baghouse Dust Collector |

| Surface | Heat Setting, Membrane, Anti Water Anti Oil Ects |

| Transport Package | Carton Case |

| Specification | 500-550g/m2 |

| Trademark | JY |

| Origin | China |

| HS Code | 8421999090 |

| Production Capacity | 100000pieces/Year |

Product Description

PPS dust filter high temperature filter bagsThe dust collector bag is made of a textile filter cloth and a non-woven felt, and the dust-containing gas is filtered using the filtering action of the fiber fabric.

Dust bag by temperature material points:

1. Ambient bag: The room temperature bag is mainly made of polyester, polypropylene, acrylic and other fibers through non-woven and textile technology. It has good air permeability, smooth surface, good dimensional stability, easy to peel off dust and other excellent performance. It is mainly used in dust removal and normal temperature flue gas treatment in industries where dust pollution occurs in general industrial enterprises.

2. Medium-temperature cloth bag: With the increasing emphasis on environmental protection by the country, especially the rapid development of bag-type dust-removing technology industry in recent years, China has begun to use imported synthetic fiber to develop conditions that can adapt to more severe working conditions. Lifetime high performance filter material. At present, the common medium-temperature filter material is aramid fiber, PPS series fiber through the immersion, waterproof, anti-oil, anti-corrosion process, so as to achieve the desired effect;

3. High-temperature cloth bags: High-temperature cloth bags are mainly made of high-strength fibers such as P84, expanded glass fiber and ultra-fine glass fiber, which are processed through spinning and non-woven processes. They are characterized by good thermal stability, high filtration efficiency and long service life. Mainly used in dust collectors under various high-temperature flue gas conditions.

Fiber Composition | Polyester | Polyester with PTFE membrane | PTFE | FMS | P84 | PPS | Nomex |

| Weight (g/m2) | 500 | 500 | 750-800 | 800 | 500 | 500-550 | 450-600 |

| Thickness (mm) | 1.7-2.0 | 1.7-2.0 | 1.2-1.6 | 1.8-3 | 2.1 | 1.8-2.0 | 1.9-2.4 |

| Running Temperature (°C) | 130 | 130 | 240 | 200 | 180 | 160 | 200 |

| Peak Temperature (°C) | 150 | 150 | 260 | 280 | 260 | 190 | 240 |

| Air Permeability (M3/M2.S. 200Pa) | 8-12 | 8-12 | 5-8 | 15 | 14 | 15 | 8-12 |

| Mechanical Finish | Singeing, calendaring, heat-set | Singeing | |||||

| Chemical Finish | membrane | Water and oil repellent | PTFE impregnated peritoneal | ||||

| Warp Of Stretch Strength | 800 | 1000 | 600 | 1400 | 900 | 900 | 900 |

| Welf Of Stretch Strength | 1200 | 1300 | 800 | 1600 | 1200 | 1200 | 1200 |

| Resistance to Acid | Medial | Fair | Excellent | Excellent | Excellen | Excellent | Fair |

| Resistance to Oxidation | Excellent | Good | Excellent | Excellent | Excellent | Poor | Fair |

| Resistance to Alkali | Medial | Poor | Excellent | Excellent | Excellent | Excellent | Good |

| Resistance to Hydrolysis | Medial | Poor | Excellent | Fair | Excellent | Excellent | Fair |

| Application | 1) The fume and smoke treatment and particle removing system in metallurgy plant 2) Smoke filtration in garbage burning, coal-feed boiler,power plant 3) Asphalt concrete mixture, cements, chemical,ceramics, building materials 4) Dust treatment, purification and collection in electronics, mining, flour and timber processing | ||||||

| Size | Φ4'' ; 5'' ; 5.25'' 6'' ; 6.62'' Length: 18'' up to 192'' | ||||||

| Filter Bag Top Construction | 1) Side Load: raw edge top (3" longer than split collar cage length) 2) Top Load: snap band/ring ; double beaded | ||||||

| Bottom Construction | 1) Single-ply felted disc bottom 2) 3" bottom; double-ply wearguard 3) 5" wear cuff with 2" overhang below bag disc bottomBottom Construction | ||||||

Filter bag | Diameter | Length | Application |

| Round bag(Filtration outside) | 120 | 2000 24002800 32003600 40004400 48005200 56006000 7000 | Pulse jet bag dust collector |

| 130 | |||

| 152 | |||

| 200 |

Prev: PPS Needle Punched Felt Filter Media Filter Bag

Next: Non Woven Needle Felt PPS Dust Filter Bag for Heat Power Plant

Our Contact

Send now