High Temperature PPS with PTFE Membrane Filter Bag for Power Plant and Boiler

Description

Basic Info

| Model NO. | FLT-FB-409 |

| Material | PPS |

| Medium Material | Synthetic Fiber |

| Cartridge Filter | Non-Woven Polyester Fiber |

| Filter Bag Filter | Outside the Filter Type |

| Type | Pocket Filter |

| Usage | Dust Filter, Liquid Filter, Air Filter |

| Filtration Grade | HEPA Filter |

| Filter Bag Sectional Shape | Round Bag |

| Filter Bag Environment | High-Temperature |

| Cartridge Installation | Vertical Lifting |

| Top Design | Carbon Steel Snapband |

| Bottom Design | Disc or Reinforcement 100mm |

| Thickness | 2.0mm |

| Width | 2.15m |

| Length | 50m/Roll |

| Surface Finishing | Singed,Calandered,Heat-Set |

| Transport Package | Carton or as Your Requirements |

| Specification | as customer requirement |

| Trademark | Filter |

| Origin | China |

| Production Capacity | 10, 000PCS |

Product Description

High temperatre PPS with PTFE membrane Filter Bag for Power Plant and Boiler:

Description:

Materials:

Needle punched Polyester,Arcylic,Aramid,PPS,P84,PTFE,Fibreglass felts for filtration are exhibiting excellent performance under wet,acid,alkali and normal-temperature and high temperature environments.

The melting temperature of all material is as high as 90oc to 300oc.

Filter Bag Top:Carbonsteel snapband&SS snapband.

Bottom:Reforcement 100mm or Disc.

Size:Customized.

PPS filter bags are used for higher temperature applications with a maximum continuous operating temperature of 160ºC.

PPS filter bags raw material is made of Japan Toray PPS high quality fiber and produced by Germany equipment to loosening, needle punching.

Technical Specification:

| Fibre | PPS |

| Scrim | PPS |

| Weight(G/M2) | 450~550 |

| Thickness (mm) | 2.2 |

| Width (mm) | ≤ 2.2 |

| Length | 50m/roll |

| Finish treatment | Singeing,Calendering,PPS dipping treatment,with PTFE membrane or oil&water repellent treatment.. |

| Air permeability (m3/m2/min): | 6~10 |

| Tensile strength (N/5× 20cm) | Warp:>900 Weft:>1200 |

| Tensile elongation (%): | Warp:<35 Weft:<50 |

| Temperature (ºC): | Continue: 170 Instant: 210 |

| Anti-acid | Excellent |

| Anti-alkali | Excellent |

| Anti-abrasion | Excellent |

| Hydrolytic stability | Excellent |

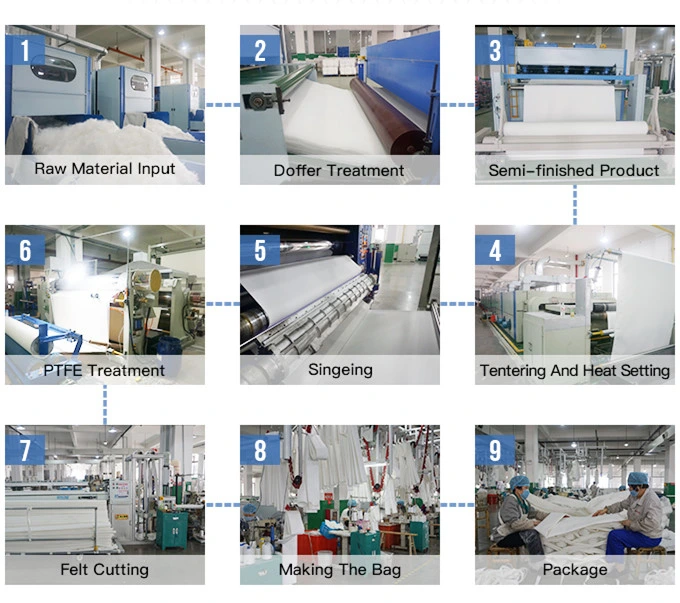

Producing Process:

Install Diagram:

Applications:

More Production:

Packaging & Delivery:

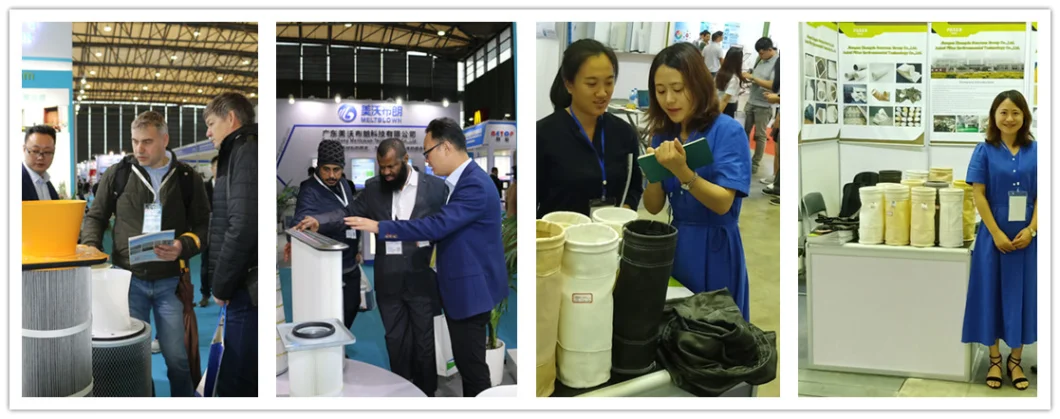

Exhibization:

Certificate:

Competitive Advantages:

1. 100% custom pass guaranteed.2. Our products have been exported to Germany, Norway, Poland, Finland, Spain, UK, France, Russia, USA, Brazil, Mexico, Australia, Japan, Korea, Thailand, Indonesia, Uruguay and many other countries.3. Flexible and Untraceable payment terms.4. Good after-sale service.

5. We offer high quality products at competitive price in quick delivery

Prev: PPS, P84, Aramid, Nomex, Fibreglass, Polyester with PTFE Membrane Filter Bags

Next: PPS Needle Felt Air Filter Bag with PTFE Membrane for Dust Collector

Our Contact