Heat Pump Low Temperature Scrap Conveyor Sludge Dryer

Description

Basic Info

| Model NO. | DY-1200WN |

| Usage | Industrial |

| Running Power | 13.5kw |

| Control | Touch Screen,PLC Programmed Controller |

| Voltage/Frequency | 380V 3h/50Hz |

| Cooling Method | Air-Cooled (FL) / Water-Cooled(SL) |

| Drying Temperature | Return Air: 48~56ºC;Supply Air: 60~80ºC |

| Wet Sludge Moisture Content | (30%-83%) (Customized) |

| Dried Sludge Moisture Content | 10%-50% |

| Refrigerant | R22/R134A |

| Forming Method | Slicing/Pelletizing (70%-83%) |

| Transport Package | Seaworthy Wooden Packing |

| Specification | 3500mm*1400mm*2300mm |

| Trademark | Diye |

| Origin | Foshan, China |

| HS Code | 8419399050 |

| Production Capacity | 70sets/Year |

Packaging & Delivery

Package size per unit product 360.00cm * 150.00cm * 240.00cm Gross weight per unit product 1600.000kgProduct Description

HEAT PUMP LOW TEMPERATURE SCRAP CONVEYOR SLUDGE DRYER

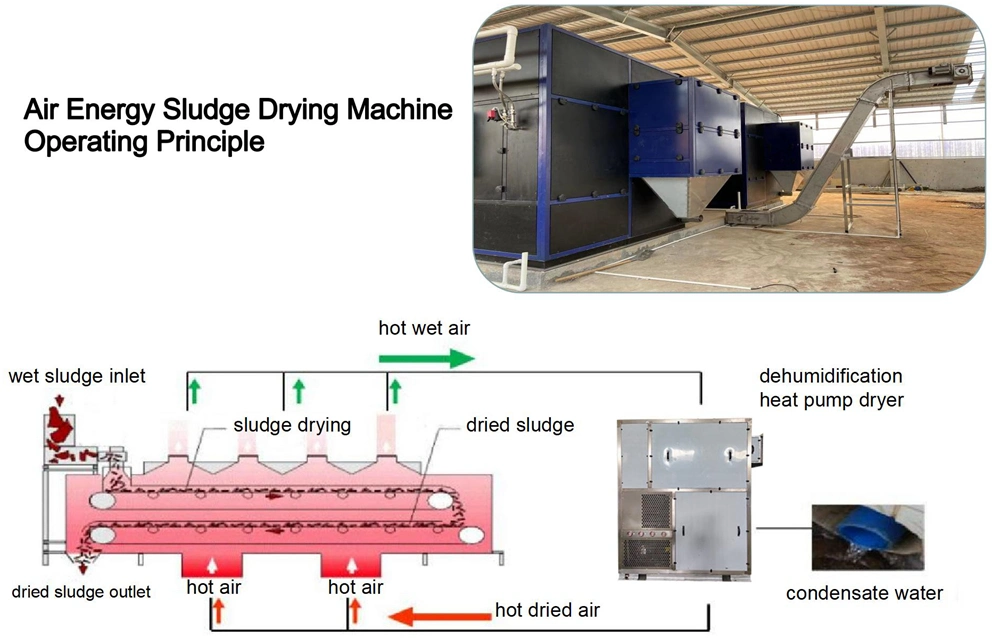

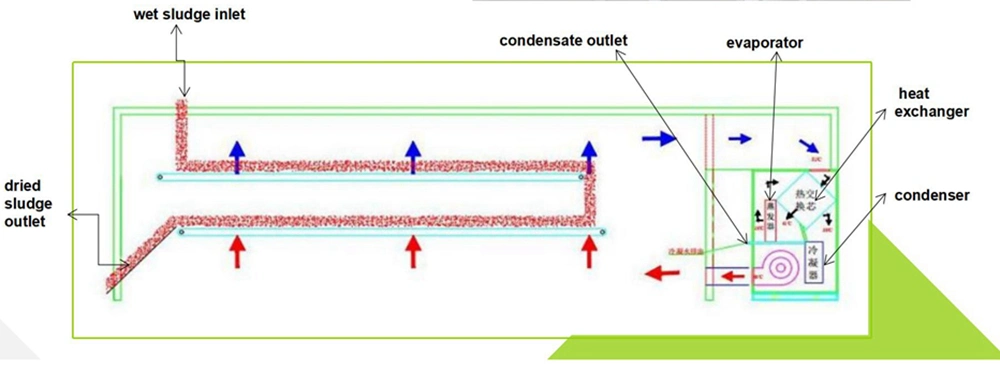

Operating Principle of Sludge Drying Equipment

Step 1: The wet sludge(moisture content 60%-80%) will be crushed,cut and squeezed into strips before entering into the sludge drying machine.Step 2: The wet low-temperature circulating air passing into the heat pump through the circulating fan and enter the heat exchanger;Step 3: The low temperature air after cooling comes out from the heat exchanger,and exchange heat energy with the evaporator to reduce the temperature; It becomes condensate water when the temperature drops to below the dew point.Step 4: Evaporated air from the intermediate cooler exchange heat energy with the heat pump; And enters the condenser after the airout temperature is increased.Step 5: The circulating air becomes hot and dry after passing through condenser before entering the sludge drying machine,Step 6: The wet sludge and the hot dry air in the drying equipment are continuously circulated and turn into about dried sludge with the moisture content of 10%-30%.

Technical Parameters

Model number | DY-1200WN | DY-2400WN | DY-4800WN | DY-9600WN | DY-14400WN | DY-24000WN |

Standard Moisture Removal | 1000kg/24h | 2000kg/24h | 4000kg/24h | 8000kg/24h | 12000kg/24h | 20000kg/24h |

Moisture Removal | 42kg/h | 84kg/h | 168kg/h | 336kg/h | 504kg/h | 840kg/h |

Running Power | 13.5Kw | 27Kw | 54Kw | 108Kw | 162Kw | 270Kw |

Heat Pump | 1pc | 1pc | 1pc | 2pcs | 3pcs | 5pcs |

Compressor | 1pc | 2pcs | 4pcs | 8pcs | 12pcs | 20pcs |

Cooling Method | Air-cooled (FL) / Water-cooled(SL) | |||||

Cooling Water Flow | 0.5m³/h | 1m³/h | 2m³/h | 4m³/h | 6m³/h | 10m³/h |

Refrigerant | R22/R134a | R22/R134a | R22/R134a | R22/R134a | R22/R134a | R22/R134a |

Voltage/Frequency | 380V 3H/50HZ | 380V 3H/50HZ | 380V 3H/50HZ | 380V 3H/50HZ | 380V 3H/50HZ | 380V 3H/50HZ |

Drying Temperature | Return Air: 48~56ºC Supply Air: 60~80ºC | |||||

Control System | Touch screen,PLC Programmed controller | |||||

Wet Sludge | Moisture content (30%-83%) (other moisture content can be customized) | |||||

Dried Sludge Moisture Content | Frequency conversion adjustment, moisture content (10%-50%) | |||||

Forming method | Slicing/Pelletizing (70%-83%) | |||||

Dimensions(L*W*H) | 3500*1400*2300mm | 3200*3000*3300mm | 4800*3000*3300mm | 8100*3000*3300mm | 11400*3000*3300mm | 18000*3000*3300mm |

Structure | integrated | assembly | assembly | assembly | assembly | assembly |

Advantages of Diye Low Temperature Sludge Drying Equipemt

The moisture content of sludge can drop from 80% to 10%-30% after drying process,and the reduction can be as high as 80%. The effective sterilization can be as high as 90%, with low energy consumption and no pollution.

High Automation

Continuous automatic operation of sludge drying is achieved due to the design of the equipment. The sludge drying process avoids the investment of manpower and reduces costs.

Energy saving and eco-friendly,no secondary pollution

The entire equipment system adopts a closed design and heat recovery technology; No heat loss, 100% heat utilization; The moisture is finally discharged in the form of condensate water and the air is recycled; There is no secondary pollution problem of exhaust gas emissions.

Low energy consumption

The low-temperature heat pump drying equipment can dry wet sludge with a moisture content of 80% per ton to 30%, and the operating cost is as low as 13.5kw/h.

Low drying temperature,less safety risks

The drying temperature is lower than 70ºC, there are few problems such as explosion and toxicity of the sludge that may volatilize; Stable operation and high utilization rate.

Application

Real Projects

Product Workflow Chart

Packaging

Certifications

Our Services

A. Order Process

INQUIRY → QUOTATION → AGREEMENT → ORDER CONFIRM → PROFORMA INOICE OR CONTRACT → DOWN PAYMENT → PRODUCTION → BALANCE PAYMENT → DELIVERY → DOCUMENTS DESPATCH → GOODS COLLECTION → INSTALLATION → OPERATION → FEEDBACK

B. OEM & ODM are welcome;

C. Technical support for your installation,operation and maintenance.

D. One year's warranty, and you can pay for extended warranty.All life time technical support.

E. Spare parts and technical support at most economic prices after the warranty.

Company Profile

Production Workshop

Prev: Heat Pump Sludge Drying Sludge Dryer

Next: Automatic Flocculant Polymer Dosing System Machinery for Chemical Plant

Our Contact