Filtration Solutions Particulate & Gas Filter Bag PE, PPS, Aramid, Fiberglass

Description

Basic Info

| Model NO. | YC-AC |

| Filter Bag Sectional Shape | Round Bag |

| Filter Bag Environment | Temperature |

| Cartridge Installation | Vertical Lifting |

| Features | Acid and Hydrolysis Resistance |

| Warranty | 12 Months |

| Certification | ISO 9001:2008 ISO 9001:2004 Cma CNAS |

| Finishing Treatment | PTFE Membrane |

| Transport Package | Cartons or Woven Bags |

| Specification | Customized |

| Trademark | Yuanchen |

| Origin | China |

| HS Code | 59119000 |

| Production Capacity | 3500 Pieces/Day |

Product Description

Bag filters are in general frequently used for dust removal in industrial applications. We make filter bags to fit most styles and types of bag houses and other dust collection systems.Filter bags come in a wide range of fabrics, coatings, finishes, sizes and configurations.Medias are available in various fabric weights and treatments such as singed, glazed, PTFEmembrane, antistatic, acid resistant and more. Features of our Acrylic filter bags:

1) Applicable to temperature 125-140 ºC 2) With good stability in acid configuration, hydrolysis and oxidation resistance3) Strong intensity4) Good finishing treatment as PTFE membrane 5) High filtration effiency when used in hydrated or slaked lime, ground raw gypsum, hemihydrate powders, where there is acid density6) Factory manufacturer with good quality and priceRemarks:1) The length of dust filter bags: Can be customized. Usual size: diameter 100mm, 125mm, 130mm, 150mm, 180mm, 250mm ect.2) Process Method: Automatic drawing, cutting, sewing on automatic production line and manual processing.3) Prodction details:Double bottoms and reinforcement to make abrasion resistance. Sewing thread: PE / PTFE thread.4) Inspection: Filter bags will be according to the national standards, industry standards and enterprise standards.5) If your required filter bag is different from our usual one, then please send us your drawing picture and choose material you need, since we also produce the nonstandard filter bag. 6) Professional designer teams to match with your operating condition.

| Technical Specification | ||

| Name/Fiber | 100% Acrylic | |

| Component | Shell Fiber | 100% Acrylic |

| Scrim | 100% Acrylic | |

| Weight | 500+5%g | |

| Thickness | 2.0mm±0.1mm | |

| Temperature | Continue | 125(ºC) |

| Peak | 140(ºC) | |

| Air Permeability | 120(L/dm².min) | |

| Elogation at break | Length | ≤30% |

| Cross | ≤50% | |

| Tensile Strength( N5*20CM) | Length | ≥700 |

| Cross | ≥800 | |

| After Treatment/Finish | Calendar,Singed,Heat-set,Antistatic,PTFEmembrane,PTFE macreate,Oil and water proof | |

| Application Field/Use Scope | Cement and Steel plant,Coal-fired power plant,Chemicial Industry,Instruction,Waste incineration plant,Circulating fluidized bed boilers,etc | |

Different types of filter bag must be individually packaged. In general, it is wrapped in plastic bags for water proof, then put in a carton. Filter bag must be neat and regular packing, with the ring of the filter bag to avoid ring flat compression deformation. For the requirement to keep the shape of filter bag, it must fill padding for filter bag inside. Any other packing ways also be accepted up to you.

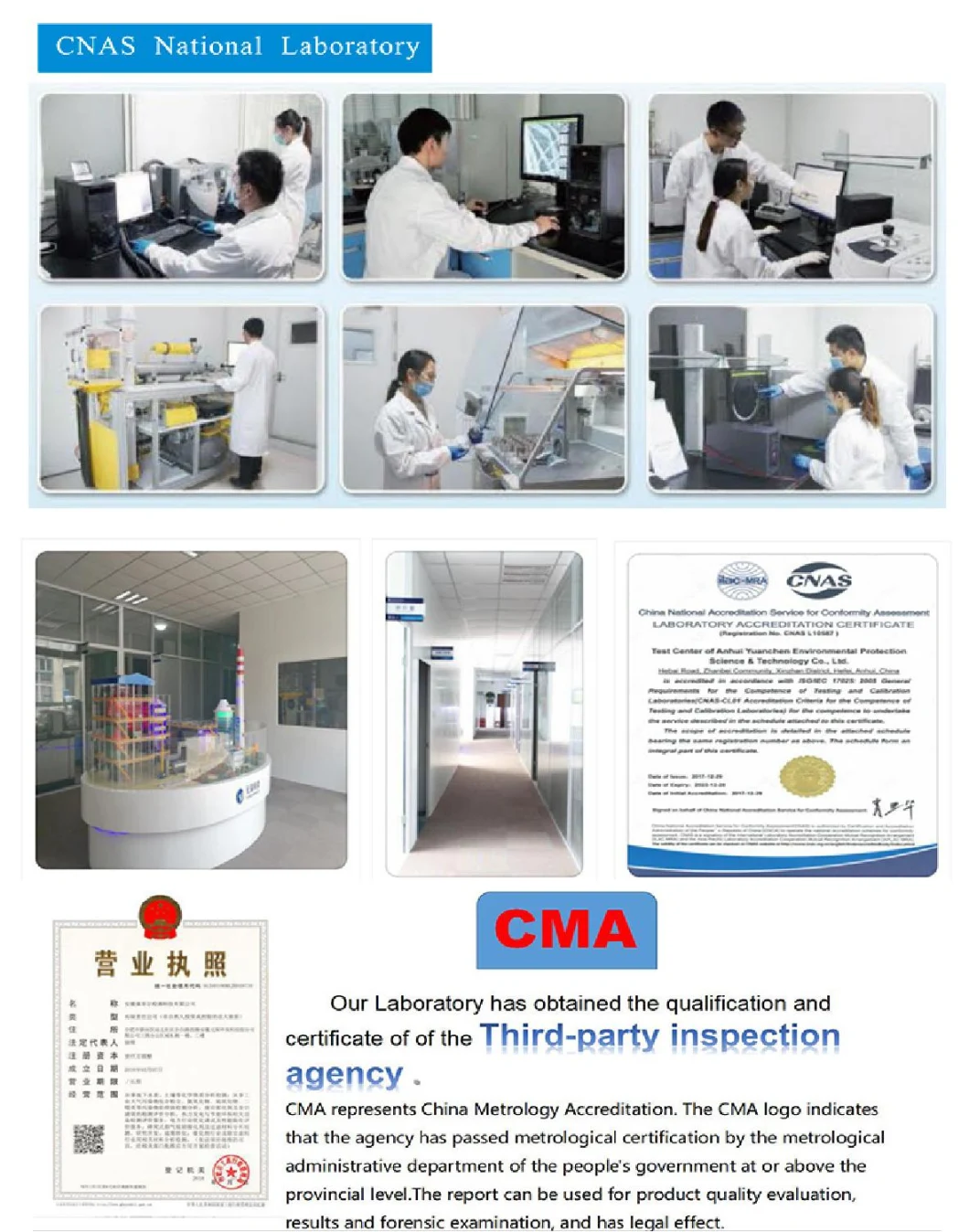

Anhui Yuanchen Environmental Protection Technology was founded in 2005 with a registered capital of 160 million yuan. It has not changed since the beginning of its development. We focus on technology development and application in the field of environmental protection, pioneering and innovating in the fields of industrial flue gas dust removal, denitrification, circular economy and intelligent environmental protection; and we are the only enterprise in China with the qualification of R&D, design and production of high-efficiency dedusting filter materials and SCR denitrification catalyst as well as recycling and reclamation of used catalysts, which has CNAS and CMA testing qualification.More than 250 skillful workers, German production technology, strict material selection, imported production equipments and managements enable us the ability to produce 10000 square meters filter cloth, 3500 filter bags and 1000 filter cages per day. We get great reputation from our clients due to good quality, reasonable price, professional consult service and huge market, etc. We are not only the supplier for filter bags, we are also the solution supplier for your removal projects, because we have professional Senior Engineers designing to meet the requirements of your industry environment.

Workshop of Filter Fabric and Bags:

Quallity Assurance:

Research Center:

Q1. What is your terms of payment?

A: T/T will usually be accepted,details could be negotiated.Q2. What is your terms of delivery?

A: FOB, CFR, CIF, DDU,EXWQ3. How about your delivery time?

A: Generally, it will take 10to 20 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order.Q4. Can you produce according to the samples?

A: Yes, we can produce by your samples or technical drawings.Q5. What is your sample policy?

A: we could offer the sample for free charge but do not pay the cost of freight.Q6. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery

Our Contact